Automated Parcel Sorting Product features:

1、Simple structure design, reliable action, does not require frequent maintenance

2、Swinging adopts stepper and servo motor, with fast response time, stable and reliable

3、Compact structure, full shield protection on the inclined wheel surface, eliminating the gap of the inclined wheel, making the sorting smooth and stable.

4、Independent control, only need to receive the sorting signal to achieve the sorting action, greatly reducing the field commissioning cycle

5. The sorter uses a stepper motor and a sensor to detect the action of the pendulum wheel, which is interlocked with the sensor signal to ensure stable and reliable sorting.

6. The front and rear rollers of the sorter are docked to reduce the gap with the front and rear docking equipment, ensuring the stability and reliability of the transport and sorting.

7、Sorting crank linkage mechanism. The well is connected with joint bearings, which can be used to make the sorting angle more flexible for on-site debugging.

8、Equipment set to adjust the foot, the site can be adjusted flexibly according to the actual situation, deceleration of installation and commissioning time

Specification:

| Item | Value |

| Place of Origin | China |

| Brand Name | Senad |

| Model Number | SND-DWSS-F100 |

| Type | Automation equipment |

| Scale | Heavy Duty |

| Capacity | 3500pph |

| Material | Carbon Steel |

| Color | Customized Color |

| Usage | Carton warehousing |

| Product name | Carton folding DWS sorting system |

| Feature | Multi-functioned |

| Application | Logistics Center |

| Certification | ISO9001,CE |

| Loading Capacity | within 50kg |

| Remark | Accepted ODM |

| Surface treatment | Spay Paint |

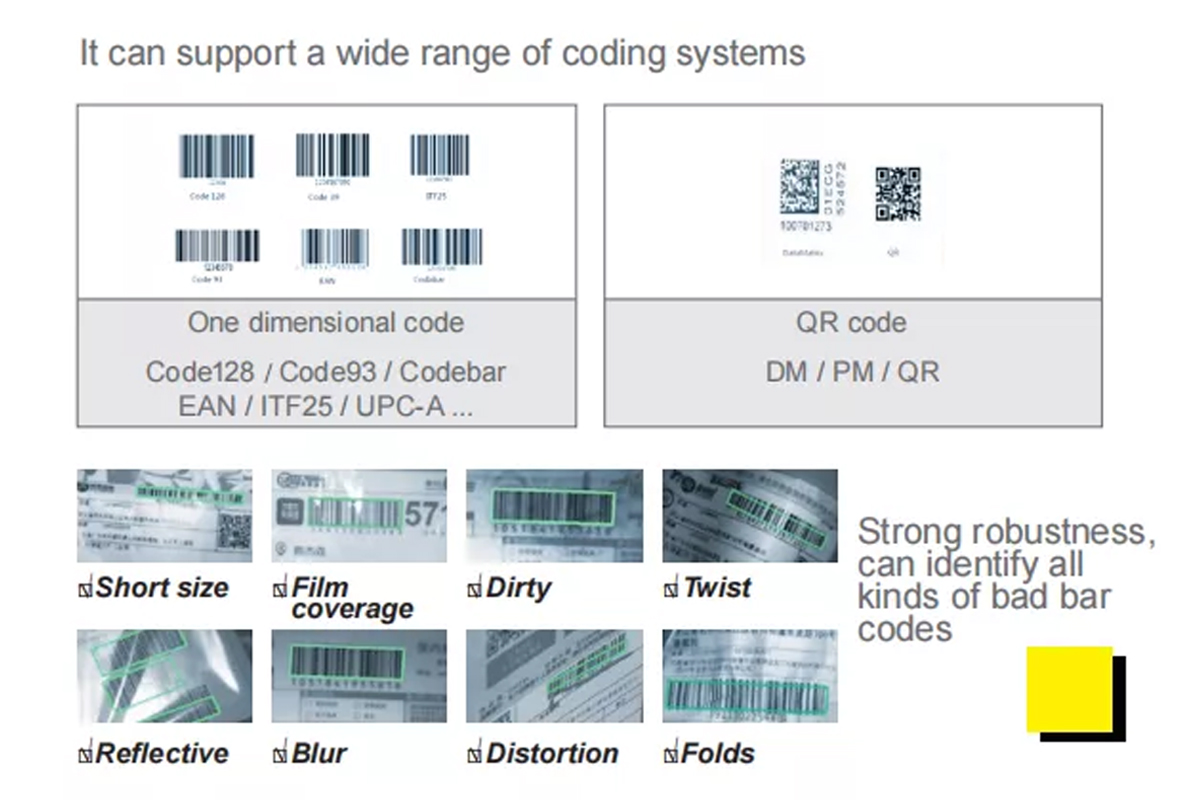

DWS Applications:

◆ E-Commerce reverse logistics

◆ Retail returns

◆ Warehouse & Distribution induction

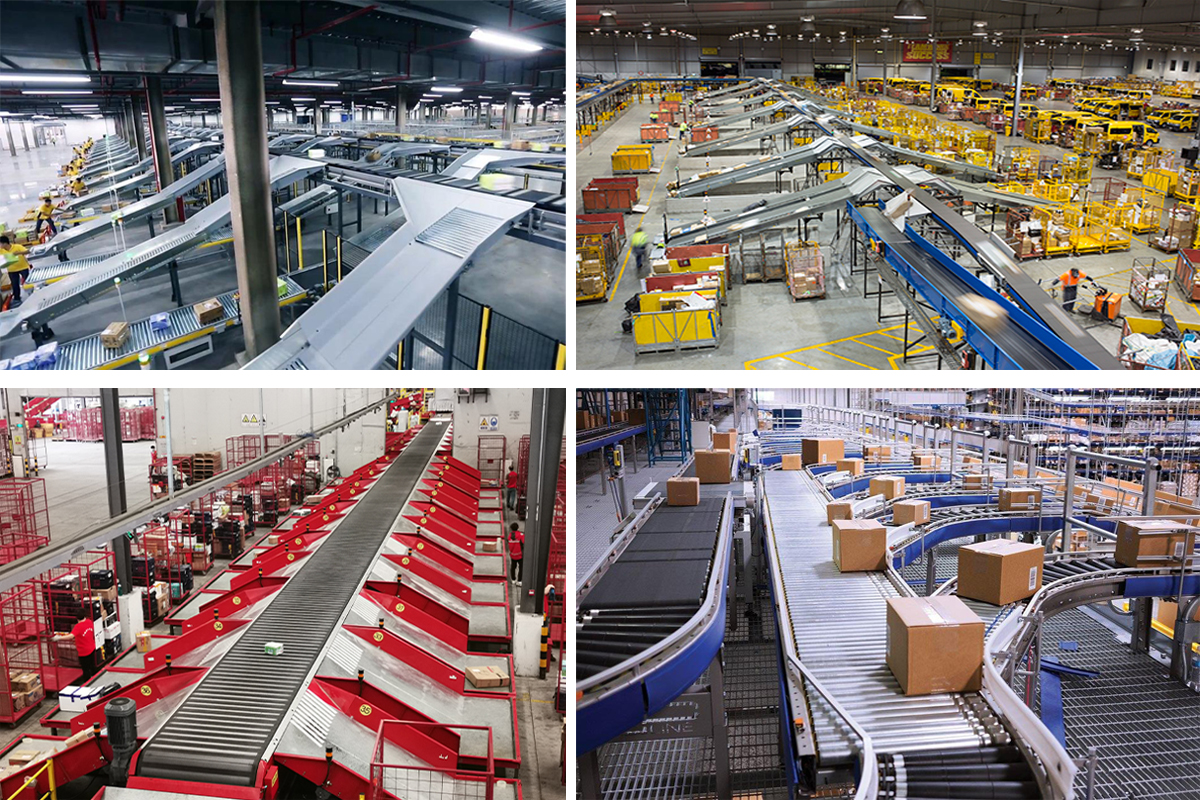

Application:

Product show & Application:

Successful Cases:

Recommend Products:

Why Choose Senad:

◆ High-tech manufacturer with research anddesign capacity

◆ Related software and system are with patents

◆ Stable and mature supplying system

◆ Young active sales and engineers for instant services(16-20 hours online)

◆ Upgrading on mechanism according to ergonomics and easy maintenance

◆ Top quality sense, customers' requests come first

◆ Our structure design principle: easy maintenance & installation, low cost maintenance, maintenance not affect production

Continue R&D and innovation in the fields of smart factory and smart storage,so that the logistics industry and manufacturing industry all over the world can enjoy the achievements of Chinese science and technology!

Q1: Is it your standard model?