Walz Goes High-Tech with In-Motion Cubing Systems for Dimensioning, Weighing & Scanning

Walz has done it again! This company is known for its innovation in industrial automation technology and its latest line of in-motion cubing systems do not disappoint. These systems are designed to simultaneously dimension, weigh, and scan boxes as they move along a conveyor system. The benefits of in-motion cubing systems are numerous, including reduced labor costs, increased accuracy, and improved logistics. In this article, we will be discussing Walz's in-motion cubing systems for dimensioning, weighing, and scanning.

Advanced Cubing and Weighing Systems

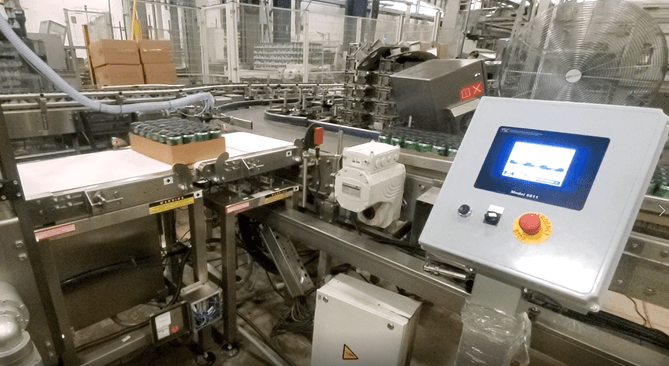

Walz specializes in designing advanced cubing and weighing systems that can handle high volumes of packages per day. Its in-motion cubing systems use a combination of sensors, lasers, and cameras to measure the dimensions and weight of a package while it moves down the conveyor system.

The cubing system is able to calculate the length, width, height, and weight of each box in real-time, and with a remarkable accuracy rate of 99%. This makes it easier for logistics companies to manage their inventory, easily sending items to the right places at the right time.

In-motion cubing systems are particularly useful for large companies that handle high volumes of packages per day. Such companies can save time and money by eliminating the need for manual labor-intensive package measurements. This reduces the likelihood of errors and improves efficiency, making operations more profitable. Given that time is very important in any logistics operation, Walz has ensured their cubing and weighing systems are lightning fast, reducing the time it takes to scan and measure each individual package to seconds.

Software Suits all Windows Devices

The software that powers Walz's in-motion cubing systems can also be used on all Windows devices. This feature makes it very user-friendly for logistics companies that use this technology. The software can be easily integrated into existing warehouse management systems to ensure seamless operations.

Senad and Walz - A Partnership for Innovation

Senad is a high-tech enterprise focused on innovation and high-end warehouse automation equipment. The company is known for its expertise in developing automated solutions that enhance efficiency and productivity. Senad is located on Floor 10th, Bldg. 5, Lane 599, Huiwang East Road, Jiading district Shanghai.

Walz's partnership with Senad has led to the development of innovative logistic automation technologies that are transforming the logistics industry. Senad's knowledge and experience has been a key factor that has enabled Walz to come up with ideas for its ground-breaking in-motion cubing systems. The two companies have been able to combine their skills and resources to design high-end warehouse automation equipment that meets the needs of the logistics industry.

Conclusion

In conclusion, Walz's in-motion cubing systems for dimensioning, weighing, and scanning are a breakthrough in the logistics industry. Their advanced technology makes work easier, more efficient, and more profitable for large companies. The software can be integrated into warehouse management systems to create flawless operations. Thanks to Walz's partnership with Senad, we can expect the industry to experience even more transformational innovations. It is not surprising that these advances in logistics automation technology are being keenly admired by business experts all over the world.