Features

Working flows

1、Put a parcel or package on the surface of middle conveyor. 2、Machine system captures the barcode value and image, and weighing sensor reads the weight. 3、System makes data processing and integrates with the sorting rules. 4、Parcel or package is automatically conveyed to the set destination.Parameters

| Parts | Configuration |

| Industrial computer | Intel I5 |

| Display | 19.5inches LCD |

| Camera | Hikvision 20 million pixel Industrial camera |

| Keyboard/mouse | Logitech |

| Load cell | 100kg |

| Bracket | Senad customized |

| Weighing range | 30g~60kg |

| Dimensioning range | 50*50*50~800*800*800mm |

| Capacity | 2500~3600pcs/hour |

| Recognition rate(Normal package) | 99% |

| Dimensioning accuracy | ±5~15mm |

| Weighing accuracy | ±20g |

| Scanning accuracy | 99% |

| Software Interface | HTTP, TCP, 485 |

| Weighing mode | Dynamic weighing |

| Remote diagnosis | yes |

| Readable barcodes | Code 128, Code 39, EAN 8, EAN 13, UPC-A, ITF25, Codebar, QR code, DM code(ECC200) |

| Functions | Read barcodes, weight, L*W*H dimensions, capture photos, convey at bi-directions, system connection |

Our services

1. Assemble and debug before delivery 2. Respond within 24 hours and proceed to deal with the problem. 3. 1 year free repair service (no-human damage only). 4. Overall warehousing solution providedWhy Choose Senad

◆ High-tech manufacturer with research anddesign capacity ◆ Concentrated on DWS equipment and sorting warehousing system overall solution ◆ Related software and system are with patents ◆ Stable and mature supplying system ◆ Young active sales and engineers for instant services(16-20 hours online) ◆ Upgrading on mechanism according to ergonomics and easy maintenance ◆ Top quality sense, customers' requests come first ◆ Our structure design principle: easy maintenance & installation, low cost maintenance, maintenance not affect production About Us:Senad Robot(Shanghai)Co.,LTD.

Founded in 2012,sanad is a national high-tech enterprise,with machine vision technology as the core,through deep learning algorithm,image processing algorithm,pattern recognition algorithm,video analysis algorithm,arm/FPGA/DSP embedded software and hardware development .industrial visual positioning .visual tracking,visual detection,multi-sensor information fusion and other technical means,in the field of smart logistics,we have found a suitable application scenario of machine vision to realize “machine generation”reduce costs and increase efficiency for enterprises ,and empower the smart logistics industry. Continue R&D and innovation in the fields of smart factory and smart storage,so that the logistics industry and manufacturing industry all over the world can enjoy the achievements of Chinese science and technology!

Our Factory:

Our Certifications:

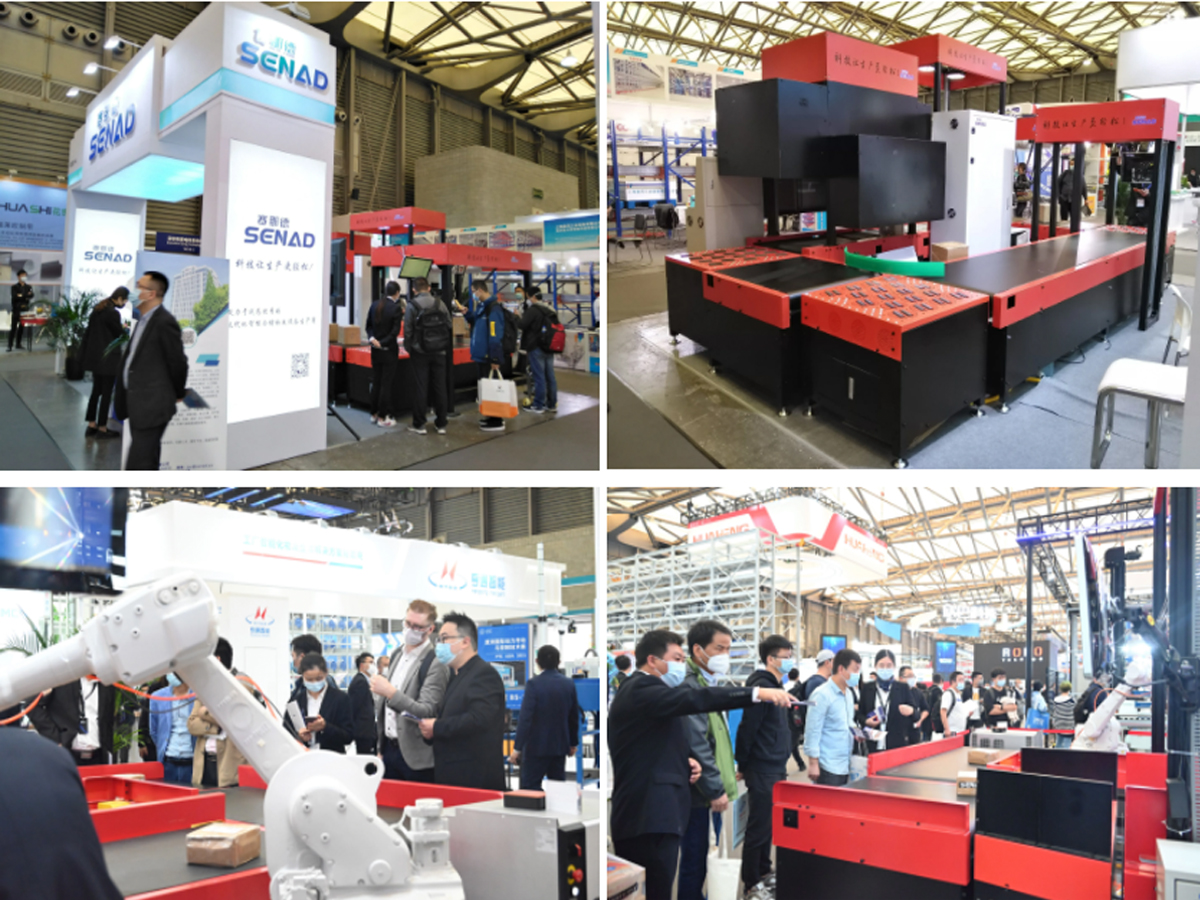

Exhibition:

Exhibition: FAQS:

Q1: Is it your standard model?

A: Yes, it is. We have standard products as well as free custom solutions

Q2: Does it require further assembly after it arrived at site?

A: No need, the machine has been fully assembled, commissioned and tested before shipment.

Q3: Is it easy to operate?

A: Yes, the oepration system and computer system can be writen in English. After opening the Vision App, the machine starts to work. The real time working status, measuring area and photoing parts, data list, barcode suppimentary input, internet connecting status and functions option frame can be clearly seen in the operatiion interface. The operator is to put the parcels/packages only.

Q4: How do you provide remote service when there’s an error?

A: There is a remote App on the desktop of PC. Open this App, the system will issue a ID and passwork, send the information to our engineer and cooperate the engineer to do the debugging.

Q5: What’s the lead time for this model?

A: It is produced every month. You can check with our sales engineer if there is stock. Otherwise, the lead time is 15-30days.